Professional Testing Items

Testing Items

G.A. Group's joint laboratory, Chuangxin Online, strictly adheres to international quality inspection standards and delivers professional test reports.

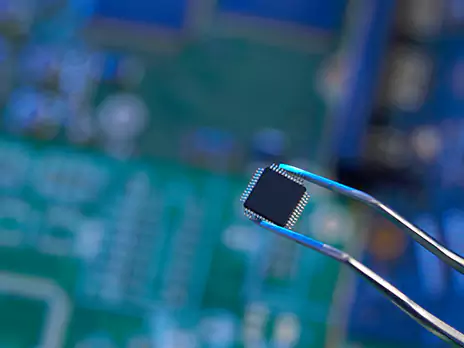

External Visual Inspection

Confirm the number of chips received, inner packaging, humidity indication, desiccant requirement, outer packaging. Perform appearance inspection on individual chips (year of production, country of origin, pin status, unknown residue, etc.)

Rohs Test

The product will be split into a single material both homogeneous material after the test, which lead, cadmium, mercury, hexavalent chromium, polybrominated biphenyls (PBB), polybrominated diphenyl ethers (PBDE) and other six hazardous substances are in line with the RoHS Directive requirements.

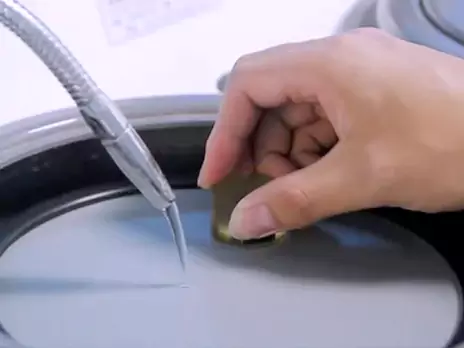

Heated Chemical Test

The chip is put into the chemical reagent and heated to a certain temperature, and the coating on the surface of the chip is peeled off by the corrosiveness of the chemical reagent to verify whether there are abrasion marks and coating problems on the surface of the chip.

X-Ray Inspection

Real-time non-destructive analysis to check the hardware components inside the component, mainly to check the chip pin frame, wafer size, gold binding diagram, etc. Customers can provide good products for comparison check.

Acetone Detection

The results are used to determine whether the chip surface is reprinted by wiping the silkscreen on the positive surface of the chip with a certain concentration of acetone in a regular manner.

Soderability Test

A qualitative and quantitative assessment of the solderable properties of components, printed circuit boards, etc. In the assembly and soldering process of electronic products, the soldering quality directly affects the quality of the whole machine.

Function Testing

Various necessary logic or signal state tests are performed under specific operating conditions (i.e., the normal operating environment of the device, usually room temperature) and in the normal operating state of the device.

Reliability Test

Activities performed to assess the functional reliability of a product over a specified life span and under all environments such as expected use, transportation or storage.

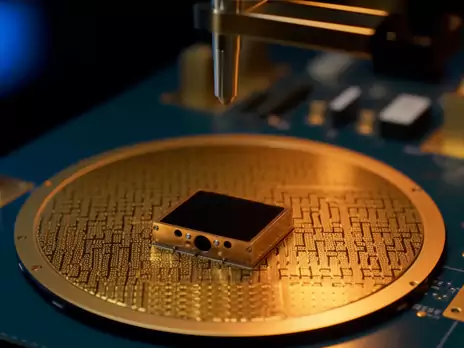

Decapsulation

The main purpose is to use the instrument to corrode the package on the surface of the chip, check whether there is a wafer inside, the size of the wafer, the manufacturer's logo, the copyright year, the wafer code, which can determine the authenticity of the chip.

Failure Analysis

Through professional failure analysis equipment, we can distinguish its failure mode and failure mechanism, confirm the final cause of failure, and make suggestions to improve the design and manufacturing process to prevent the recurrence of failure.

Electrical Test

According to the device pins and related instructions specified by the manufacturer in the specification, use a semiconductor tube characteristic grapher to check whether the chip is damaged by open-circuit and short-circuit tests.

Ultrasonic Scanning (SAT detection)

This is a nondestructive inspection method that discriminates the difference in acoustic impedance within the material, determines the shape and size of the defect, and determines the orientation of the defect through image contrast.

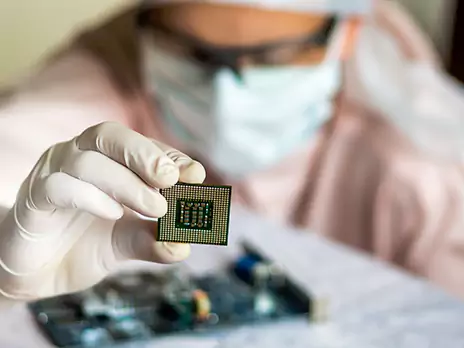

IC Authenticity Detection

It is a chip made by putting a lot of integrated circuits of microelectronic components on a plastic substrate.

Slicing Test

It is one of the most common means of sample preparation and analysis to observe the cross-sectional structure of the sample, to determine the quality of analysis and inspection of circuit boards, etc.

Label Inspection

It is a comparative analysis based on the photos of the label provided by the customer and the original label, official website information, etc., so as to identify its authenticity.

Metallographic Sections

It refers to the cutting open of materials or devices, which requires wrapping and fixing the sample, grinding and polishing, and then observing the tissue structure through electron microscopy and drawing conclusions about the test.

New Product Development Testing

Through test equipment, we write test vectors according to new product specifications and help customers develop tests, which are generally available only after the product is packaged.